Top China Manufacturer of Alligator Clips for Quality Connections

When it comes to sourcing high-quality alligator clips, I find that partnering with a reliable manufacturer in China makes all the difference. These clips are not just essential tools for various electronic projects; they are built to last and designed for efficiency. From testing circuits to creating robust connections, their versatility meets diverse needs across multiple industries. Working directly with experienced Chinese manufacturers ensures that I get the best materials and production techniques. This means I can offer products that meet stringent quality standards while also being cost-effective. Plus, the ability to customize designs and specifications is a huge advantage for B2B purchases. In my experience, establishing a strong business relationship with a trustworthy supplier leads to better pricing and faster turnaround times. If you’re in the market for alligator clips, let’s connect and discuss how we can meet your specific needs and elevate your project success!

Alligator Clips Trusted by Pros Pioneers in the Field

When it comes to reliable connections in various applications, alligator clips have become indispensable tools trusted by professionals across many fields. These versatile connectors serve a vital role in electrical testing, prototype development, and in laboratories where prompt and secure connections are essential. Their design, typically featuring a spring-loaded jaw that can easily clamp onto wires or terminals, ensures a strong grip and a reliable electrical connection. For global procurement officers seeking high-quality connectors, finding a trusted supplier that understands the nuances of manufacturing excellence is crucial. Alligator clips that demonstrate superior conductivity, durability, and resistance to wear and tear play a significant role in maintaining the integrity of any project. Professionals rely on these clips not just for their functionality but also for their consistency under varying environmental conditions. By investing in alligator clips that meet stringent quality standards, businesses can enhance their operational efficiency and reduce the likelihood of failure in critical applications. Furthermore, as industries evolve and innovate, the demand for advanced alligator clip designs continues to grow. Companies are encouraged to stay ahead by choosing suppliers that prioritize research and development, ensuring that their products reflect the latest technological advancements. By partnering with leaders in the field, procurement teams can secure the best products available, giving their projects a competitive edge and fostering long-term success.

Alligator Clips Trusted by Pros Pioneers in the Field

| Clip Type | Material | Max Current Rating (A) | Color Options | Application Area |

|---|---|---|---|---|

| Standard Alligator Clip | Copper | 25 | Red, Black, Green | Electrical Testing |

| Heavy Duty Clip | Stainless Steel | 40 | Black, Yellow | Automotive Repair |

| Mini Alligator Clip | Nickel-plated Steel | 10 | Red, Blue | Lab Experiments |

| Insulated Alligator Clip | Copper | 30 | Red, Black, Yellow | DIY Projects |

| Professional Electrical Clip | Brass | 50 | Red, Green, Black | Circuit Design |

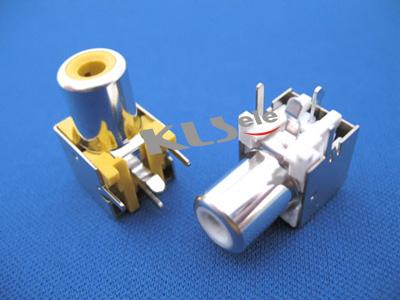

Related Products

_1.jpg)

_1.jpg)

_1.jpg)

_1.jpg)

_1.jpg)