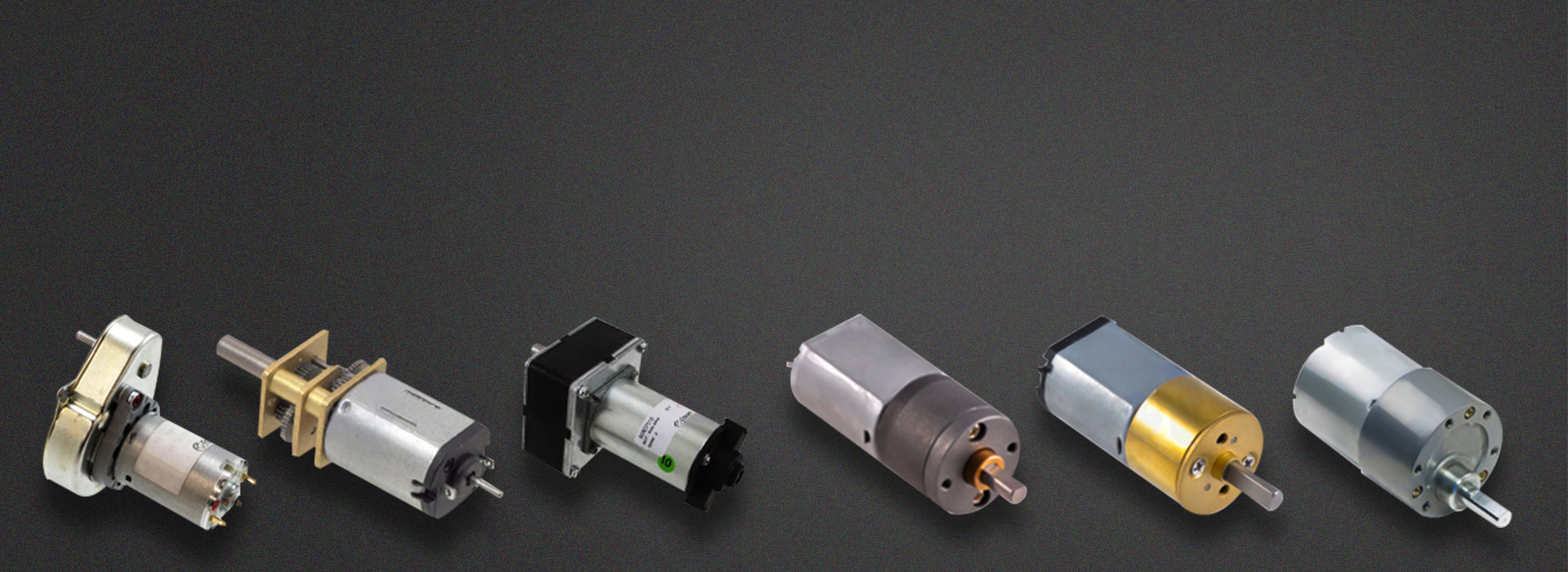

High-Quality DC Gear Motors Reduction from Leading China Manufacturer

When it comes to reliable DC gear motors with reduction features, I've found that quality and performance are key. Sourced from top manufacturers in China, our gear motors are designed for efficiency and longevity. I appreciate how these motors can easily adapt to various applications, from robotics to automotive. With the reduction capabilities, they ensure precise control over speed and torque, making them perfect for your project requirements. What I find impressive is the attention to detail in the manufacturing process, which truly sets our products apart. Each gear motor I’ve used has demonstrated exceptional durability and has exceeded my expectations in both function and reliability. Partnering with a trusted Chinese manufacturer gives me confidence that I'm getting not just a product, but a promise of quality and innovation. If you're seeking dependable gear motors to enhance your operations, these options are worth considering.

Dc Gear Motors-Reduction Factory Is The Best

When it comes to sourcing high-quality DC gear motors, partnering with a top-notch reduction factory is essential for global buyers. These motors are designed to provide exceptional torque and precise speed control, making them an ideal choice for a variety of applications, from robotics to automation and beyond. A leading reduction factory stands out not just for its products but also for its commitment to innovation, quality assurance, and customer satisfaction. One of the key advantages of choosing the best DC gear motors from a reputable manufacturer is the emphasis on advanced engineering and technology. Such factories integrate cutting-edge manufacturing processes with rigorous testing protocols, ensuring that each motor meets international standards. This not only enhances the performance of the motors but also extends their lifespan, allowing businesses to operate efficiently and reduce maintenance costs. Moreover, a reliable reduction factory values strong communication and support for its clients. Global buyers benefit from dedicated teams that understand the complexities of international procurement, offering tailored solutions and timely assistance throughout the buying process. By prioritizing quality, innovation, and excellent customer service, a top-tier DC gear motor manufacturer positions itself as a strategic partner for businesses looking to enhance their operations and achieve lasting success in the market.

| Motor Type | Voltage (V) | Torque (Nm) | Speed (RPM) | Efficiency (%) |

|---|---|---|---|---|

| DC Motor A | 12 | 1.5 | 200 | 85 |

| DC Motor B | 24 | 3.0 | 100 | 90 |

| DC Motor C | 6 | 0.5 | 300 | 82 |

| DC Motor D | 36 | 4.0 | 50 | 88 |

| DC Motor E | 48 | 5.5 | 30 | 87 |

Related Products

_1.jpg)