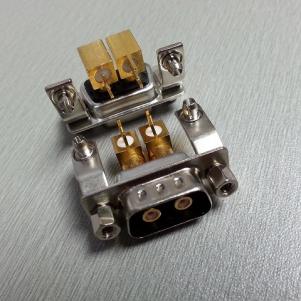

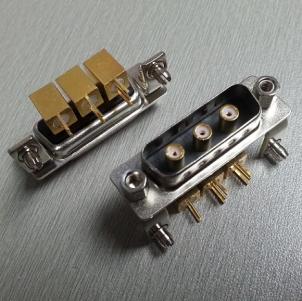

High Current D-Sub Connectors Manufacturer in China - Quality Solutions

Are you in need of reliable High Current D-Sub Connectors for your projects? As a dedicated manufacturer based in China, I understand the critical role these connectors play in ensuring efficient electrical connections. Our High Current D-Sub Connectors are designed to handle higher current loads while maintaining excellent performance and durability. We take pride in our stringent quality control measures, ensuring that each connector meets international standards. Whether you’re integrating them into industrial machinery or electronic devices, our connectors provide the robustness and reliability you require. With a variety of configurations available, finding the right fit for your application is easy. Partnering with us means you get personalized service and competitive pricing, making it a win-win for your business. Don’t settle for less when it comes to your electrical connectivity needs—trust in our expertly crafted connectors to get the job done right! Reach out today to learn more about our products and how they can benefit you.

High Current D-Sub Connectors in 2025 Now Trending

In 2025, the demand for high current D-Sub connectors is experiencing a significant rise, driven by advancements in technology and the increasing need for robust electrical solutions across various industries. These connectors, known for their reliability and efficiency, are becoming an essential component in medical devices, telecommunications, automotive applications, and industrial automation. With the growing focus on energy efficiency and high-performance systems, manufacturers are seeking connectors that can handle higher currents while maintaining a compact form factor. As industries evolve, the ability to integrate high current D-Sub connectors into existing systems will prove crucial. These connectors are designed to provide superior electrical performance, ensuring stable connections in demanding environments. Their popularity is bolstered by innovations in materials and designs that enhance durability and resistance to environmental factors, making them suitable for outdoor and rugged applications. Additionally, the trend toward automation and smart technologies is fueling the need for advanced connection solutions that can support higher data transfer rates and better power management. For global buyers, staying ahead of these trends means sourcing high-quality D-Sub connectors that not only meet current demands but are also adaptable for future applications. Collaborating with suppliers who are proactive in product development and innovation will be key to ensuring access to the latest technologies. As the market continues to shift toward more complex and high-demand applications, aligning with reliable manufacturers will provide a competitive edge in an increasingly interconnected world.

High Current D-Sub Connectors in 2025 Now Trending

| Connector Type | Current Rating (A) | Pin Count | Material | Application |

|---|---|---|---|---|

| D-Sub 15 Pin | 20 | 15 | Steel | Industrial Automation |

| D-Sub 25 Pin | 30 | 25 | Copper | Telecommunications |

| High Density D-Sub 37 Pin | 15 | 37 | Nickel | Medical Equipment |

| D-Sub 9 Pin | 10 | 9 | Aluminum | Consumer Electronics |

| Dual Port D-Sub | 25 | 25 | Plastic | Data Communication |

Related Products

_1.jpg)