Top China Manufacturer of Te Amp Automotive Connectors for Reliable Performance

When it comes to reliable automotive connections, I trust Te Amp Automotive Connectors. As a buyer, I appreciate the quality and performance these connectors deliver, especially when sourced from a reputable manufacturer in China. They provide a perfect blend of durability and efficiency, ensuring that my automotive applications run smoothly without failures. I’ve noticed that the connectors are designed to withstand harsh environments, making them ideal for various automotive applications. The ease of installation also saves me valuable time—something every B2B purchaser can appreciate! Working directly with a China manufacturer, I benefit from competitive pricing and prompt service. This enables my projects to stay on schedule without compromising on quality. With Te Amp Automotive Connectors, I’m confident in the reliability of my connections. That's why I recommend them to anyone seeking high-performance automotive solutions!

Te Amp Automotive Connectors in 2025 Where Service Meets Innovation

In 2025, the automotive industry is poised for a transformative shift, particularly regarding connectivity and service solutions. As vehicles evolve into highly integrated systems connecting drivers to a multitude of services, the role of innovative connectors is becoming increasingly crucial. These automotive connectors will not only ensure seamless communication between various components, but they will also facilitate an enhanced user experience, enabling features such as real-time diagnostics, infotainment systems, and advanced driver assistance technologies. As the demand for electric and autonomous vehicles surges, the performance and reliability of connectors will be put to the test. New materials and designs will need to address the challenges posed by higher voltages and temperatures, ensuring safety and durability. In this context, the convergence of service and innovation becomes critical, as companies must harness cutting-edge technologies to meet the evolving needs of both manufacturers and end-users. Adopting industry best practices and innovative manufacturing techniques will be essential in developing automotive connectors that not only meet regulatory standards but also provide long-term value and sustainability. Global procurement professionals must stay ahead of these trends to ensure they source the most advanced and reliable connector solutions available. By forging partnerships with manufacturers who prioritize research and development, procurement teams can secure components that enhance vehicle performance while promoting service innovations. As 2025 approaches, the synergy between automotive connectors and technological advancements will define the future of mobility, underscoring the importance of strategic sourcing in this dynamic landscape.

Te Amp Automotive Connectors in 2025 Where Service Meets Innovation

| Connector Type | Material | Temperature Range (°C) | IP Rating | Applications |

|---|---|---|---|---|

| Sealed Connector | Polymer | -40 to 125 | IP67 | Powertrain, Chassis |

| High Voltage Connector | Thermoplastic | -30 to 150 | IP68 | Battery Systems, EV |

| Data Connector | Metal Alloy | -40 to 125 | IP54 | Infotainment, Telematics |

| Signal Connector | Thermoplastic Elastomer | -30 to 125 | IP65 | Body Control, Advanced Driver Assistance Systems |

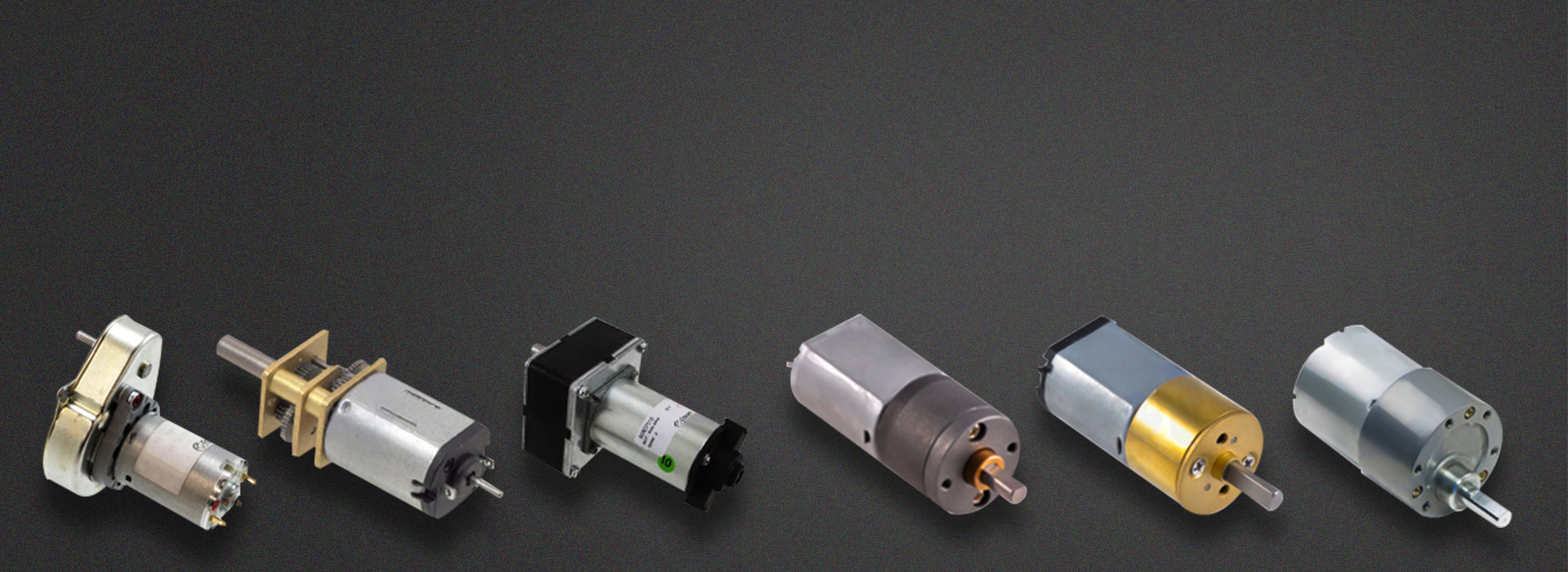

Related Products

_1.jpg)