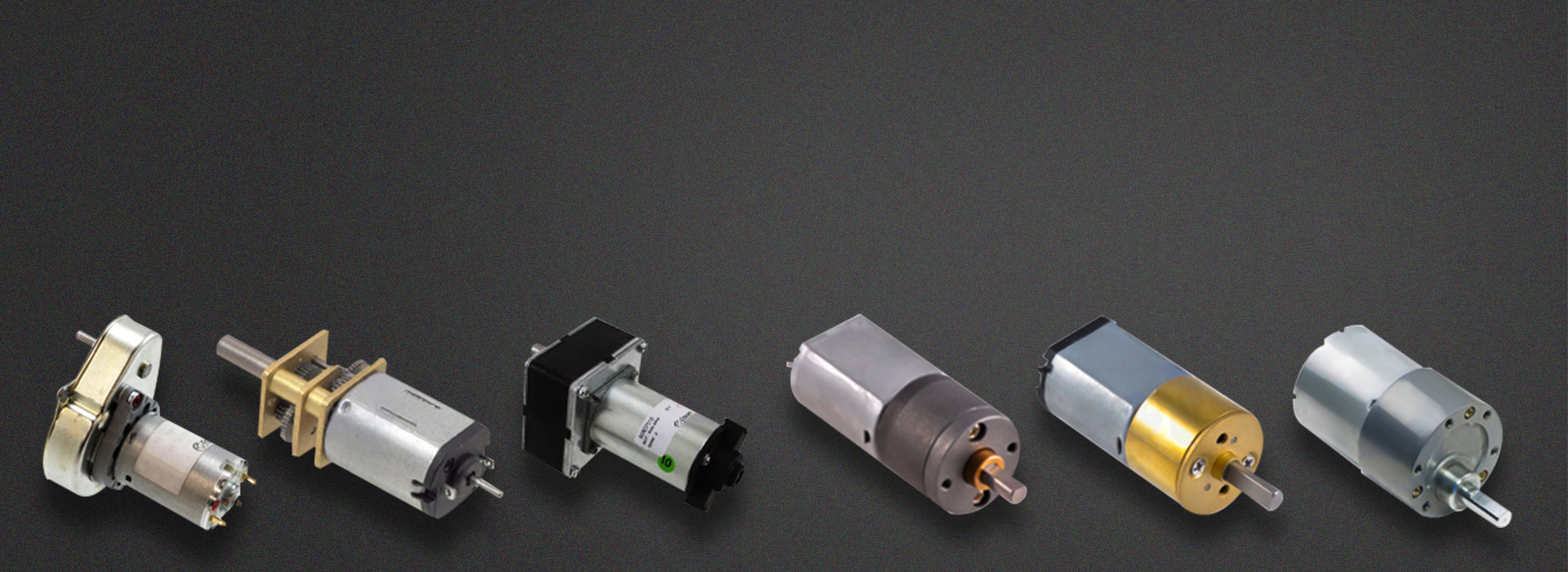

DC Brushless Gear Motors-Reduction from Leading Manufacturer in China

When I needed reliable and efficient DC brushless gear motors with reduction, I found that sourcing from experienced manufacturers in China made all the difference. These motors are designed to deliver high torque and precision, ideal for a wide range of applications—from robotics to automation systems. I've seen firsthand how the advanced design minimizes energy loss while maximizing performance. Working with a trustworthy Chinese manufacturer means I get consistent quality, timely deliveries, and competitive pricing. Plus, the low maintenance requirements of these gear motors save both time and resources in my operations. If you’re in the market for top-notch DC brushless gear motors, I can assure you that partnering with a reputable source in China will enhance your project’s success. Let’s take a step towards boosting efficiency together!

Dc Brushless Gear Motors-Reduction Where Innovation Meets 2025 Factory-Direct Excellence

In the rapidly evolving world of automation and robotics, the demand for high-performance, energy-efficient solutions has never been greater. Enter DC Brushless Gear Motors, a technology that is setting new standards for reliability and efficiency. These motors are specifically designed to offer superior torque and speed control, making them ideal for various applications, from industrial machinery to consumer electronics. With the advent of smart technology, manufacturers are continuously innovating to meet the diverse needs of their global clientele, ensuring that every product is optimized for performance while maintaining cost-effectiveness. The integration of a reduction mechanism in brushless gear motors further enhances their functionality. This innovation allows for greater power output while minimizing energy consumption, fulfilling the industry's need for sustainable solutions. As businesses across the globe seek to trim down operational costs without sacrificing quality, factory-direct options become increasingly appealing. These manufacturers have streamlined their production processes, enabling them to offer unparalleled value to procurement professionals who demand high-quality products at competitive prices. As we look ahead to 2025 and beyond, the focus on direct factory partnerships will transform the way companies source their motor solutions. By working directly with manufacturers, buyers can ensure they are receiving cutting-edge technology tailored to the specific needs of their applications. This trend toward efficiency and innovation not only propels industries forward but also guarantees that businesses remain agile and competitive in an ever-changing market landscape.

| Motor Type | Voltage (V) | Power Rating (W) | Torque (Nm) | Speed (RPM) | Reduction Ratio | Efficiency (%) |

|---|---|---|---|---|---|---|

| High Torque | 24 | 150 | 2.5 | 200 | 15:1 | 85 |

| Standard | 12 | 80 | 1.2 | 300 | 10:1 | 80 |

| Low Speed | 36 | 100 | 1.5 | 100 | 20:1 | 90 |

| Compact | 48 | 60 | 0.8 | 400 | 5:1 | 78 |

Related Products

_1.jpg)

_1.jpg)